Pharma

applications

From engineering to production,

from testing to technical support.

Nasal spray

Description

These are an automatic filling lines suitable to handle rigid containers for aerosol and 1 inch valves.

The machines bodies consist of a frames and crankcases made of AISI 304 stainless steel.

Inside the crankcases there are the indexing electrical motor drive and the pneumatic system, which move the star wheel and the operating units.

Available the electronic version equipped by brushless electrical motor and the electric-pneumatic system.

It could be features from 12, 18, 24 or 32 position rotating star wheel or rotary index mode, that can support cans with a maximum diameter of 66mm and minimum height of 70mm.

On the baseplate of the machines, there is a central adjustable column, on which the operating units are housed.

All the parts in contact with the product are made of AISI 316 stainless steel (AISI 316L on request) and all gaskets are accurately selected to be the best fit for your needs.

There are protective shatterproof glasses that surround all the moving parts that may be dangerous to the operators.

Depending on the model, the number of the devices installed and the production speed required, machines can run single indexing, multiple indexing or rotary mode.

The machines is designed and manufactured to be extremely versatile, as well as extremely reliable and safe. All units comply with the up to dated norms of the European Economical Community (CE mark) and are designed to operate in Atex Areas.

The process is specifically designed to fill isotonic saline water.

All the material of the machine that can be in contact with saline water must be in AISI316 or protected aluminium.

Standard units available on this line

• Filling product unit (gasket in contact with product must be resistant to silicon liquid)

• Automatic inserting aerosol valve unit

• Crimping of the aerosol valve unit

• Gassing unit

• Hot water bath test

• Checkweigher system

• Actuator placing unit

• Cap placing unit

• Others special devices available on request

Topic product

Description

These are an automatic filling lines suitable to handle rigid containers for aerosol and 1 inch valves.

The machines bodies consist of a frames and crankcases made of AISI 304 stainless steel.

Inside the crankcases there are the indexing electrical motor drive and the pneumatic system, which move the star wheel and the operating units.

Available the electronic version equipped by brushless electrical motor and the electric-pneumatic system.

It could be features from 12, 18, 24 or 32 position rotating star wheel or rotary index mode, that can support cans with a maximum diameter of 66mm and minimum height of 70mm.

On the baseplate of the machines, there is a central adjustable column, on which the operating units are housed.

All the parts in contact with the product are made of AISI 316 stainless steel (AISI 316L on request) and all gaskets are accurately selected to be the best fit for your needs.

There are protective shatterproof glasses that surround all the moving parts that may be dangerous to the operators.

Depending on the model, the number of the devices installed and the production speed required, machines can run single indexing, multiple indexing or rotary mode.

The machines is designed and manufactured to be extremely versatile, as well as extremely reliable and safe. All units comply with the up to dated norms of the European Economical Community (CE mark) and are designed to operate in Atex Areas.

The process is specifically designed to fill topic product.

Standard units available on this line

• Filling product unit with recycle system for powder suspension product

• Automatic inserting aerosol valve unit

• Crimping of the aerosol valve unit

• Gassing unit

• Hot water bath test

• Checkweigher system

• Actuator placing unit

• Cap placing unit

• Others special devices available on request.

pMDI

Description

The pMDIs process is a specific pharmaceutical filling system. Cosmar has acquired team of specialist in process, design and formulation able to respond to the pharmaceutical market for MDIs.

The cooperation with the University of Parma gives Cosmar added value in well managing the whole process, included the different formulations.

Cosmar is able to provide single stage and double stage filling equipment.

Special clean room systems are applied on the machine to respect the zoning.

Laboratory equipment can be provided for validation process able to cover the following phases:

MDI Double Stage filling process

1. Filling of product in open cans (where ethanol is used this is already able to remove air)

2. insertion of valve onto cans

3. Purging with HFA through the valve (optional)

4. Vacuum inside cans

5. Crimping of valve

6. Filling of pure propellant through crimped valves

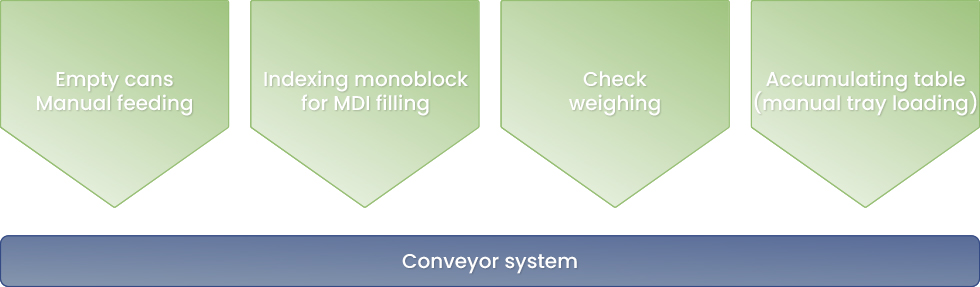

Exemple of Process Flow Layout

Primary packaging area

Cosmar is also able to provide process tank, mixing vessel, piping and pumping system.

ASK FOR A QUOTE!

Request here the quote for your new line for the cosmetic sector.